Calibration services are essential for businesses and industries to ensure that their equipment and instruments are operating at the highest electrical instrument calibration level of accuracy and efficiency. Professional calibration services can help enhance overall productivity and cost-effectiveness by maintaining the precision and reliability of critical assets. In this article, we will discuss how calibration services can contribute to the enhancement of efficiency in various sectors and the importance of seeking professional assistance for this crucial task.

Professional calibration services can help enhance efficiency by ensuring that equipment and instruments are operating at their optimal performance levels. By regularly calibrating tools and machinery, businesses can minimize downtime, reduce the risk of errors, and improve overall productivity. Additionally, professional calibration services can help organizations comply with industry regulations and standards, further contributing to their efficiency and effectiveness. With the expert electrical calibration equipment knowledge and precision of calibration technicians, businesses can have confidence in the accuracy and reliability of their equipment, ultimately leading to improved operational efficiency and performance.

The Importance of Regular Calibration Services for Industrial Equipment

Calibration services are essential for ensuring the accuracy, reliability, and quality of industrial equipment. Regular calibration helps to maintain consistency in measurements and ensures that the equipment is functioning at its optimal level. This is particularly important for industries that rely heavily on precision, such as manufacturing, aerospace, pharmaceuticals, and healthcare. Regular calibration also helps to identify and address any potential issues or discrepancies in the equipment. This proactive approach can prevent costly downtime, errors, and safety hazards. Additionally, many industries are required to comply with strict regulations and standards, and regular calibration is necessary to meet these requirements. By investing in regular calibration services, industrial companies can improve their operational efficiency, reduce the risk of product load cell calibration equipment defects or errors, and ultimately save time and money in the long run. It is an essential part of maintaining the overall reliability and performance of industrial equipment.

Choosing the Right Provider for Your Calibration Services

When choosing the right provider for your calibration services, it's important to consider factors such as the provider's accreditations, expertise in your specific industry, turnaround time, cost, and customer service. Look for a provider that is accredited by a recognized organization such as ISO/IEC 17025, as this demonstrates their commitment to quality and competency. Additionally, consider the provider's experience and track record in calibrating equipment similar to yours. Turnaround time is also a crucial factor to consider, especially if your operations are time-sensitive. Inquire about the provider's typical turnaround time for calibrations and whether they offer expedited services if needed. Cost is another consideration, but it's essential to balance cost with the quality of service provided. Lastly, assess the provider's customer service and communication practices. A responsive and helpful provider can make a significant difference in your overall experience with calibration services. Take the time to research and compare different providers to ensure you make the best choice for your calibration needs.

Maximizing Efficiency: The Advantages of Calibration Services for Businesses

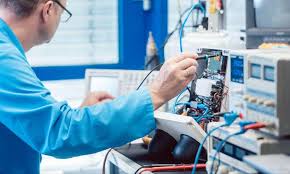

onsite calibration services

Maximizing efficiency through calibration services offers businesses a range of benefits. Calibration ensures that equipment and tools are operating at peak accuracy and reliability, reducing the risk of error and saving time and resources. It also helps maintain regulatory compliance and improve overall quality control. By outsourcing calibration services to experienced professionals, businesses can focus on their core operations while maximizing the performance and longevity of their equipment. This ultimately leads to increased productivity and cost savings, making calibration services a valuable investment for businesses across various industries.

Understanding the Benefits of Traceable Calibration Services

Traceable calibration services provide the assurance that the measurements and test equipment used in your processes are accurate and reliable. These services ensure that the equipment is calibrated to international or national standards, which can be traced back to a recognized authority. By using traceable calibration services, organizations can have confidence in the accuracy of their measurements, leading to improved product quality, increased efficiency, and reduced risk of errors. Additionally, traceable calibrations are often required to meet regulatory and quality management system requirements. Overall, understanding the benefits of traceable calibration services can help organizations maintain the quality and consistency of their products and services, as well as ensure compliance with industry standards and regulations.

Essential Calibration Services Every Laboratory Should Invest In

Essential calibration services that every laboratory should invest in include regular calibration of equipment such as pipettes, balances, spectrophotometers, and pH meters. These services ensure that the instruments are providing accurate and reliable data, which is crucial for maintaining the quality of laboratory results. In addition, investing in calibration services for temperature and humidity monitoring devices is important for ensuring the environmental conditions within the laboratory are optimal for the experiments being conducted. Finally, it is essential to invest in calibration services for safety equipment such as fume hoods and biosafety cabinets to ensure the protection of laboratory personnel and the integrity of the work being conducted.

The Role of Accredited Calibration Services in Regulatory Compliance

Accredited calibration services play a critical role in ensuring regulatory compliance for businesses in various industries. These services help companies meet the standards and requirements set forth by regulatory bodies such as the International Organization for Standardization (ISO) and the Food and Drug Administration (FDA). By using accredited calibration services, businesses can ensure that their measurement and testing equipment meet the necessary accuracy and precision standards. This is essential for industries such as healthcare, aerospace, manufacturing, and environmental monitoring, where reliable and accurate measurements are crucial for both product quality and safety. In addition, accredited calibration services provide traceable documentation and certificates that demonstrate compliance with regulatory requirements. This is important for audits and inspections by regulatory agencies. Furthermore, using accredited calibration services can help businesses avoid costly fines and penalties for non-compliance. Overall, accredited calibration services are indispensable for companies seeking to maintain regulatory compliance and uphold the highest standards of quality and safety in their products and processes.

Improving Quality Control with Precision Calibration Services

Precision calibration services can significantly improve quality control by ensuring that measuring and testing equipment is accurate and reliable. This can help to minimize production errors, reduce rework and scrap, and ultimately improve product quality. Properly calibrated equipment also helps to ensure that products meet regulatory and industry standards, enhancing customer satisfaction and reducing the risk of costly recalls or non-compliance issues. Regular calibration can also extend the lifespan of equipment and optimize its performance, ultimately leading to cost savings and improved efficiency. Overall, precision calibration services play a crucial role in enhancing quality control and contributing to overall operational excellence.

Investing in Calibration Services: Long-Term Cost Savings for Your Business

Investing in calibration services can result in long-term cost savings for your business by ensuring that your equipment and instruments are operating accurately and efficiently. By regularly calibrating your equipment, you can prevent costly errors and production downtime. Additionally, calibration services can help extend the lifespan of your equipment, reducing the need for frequent repairs or replacements. Properly calibrated equipment also leads to higher quality output, reducing the risk of product defects and potential recalls. Overall, investing in calibration services is a proactive way to save money and maintain the integrity of your business operations.

Calibration Services: Ensuring Accuracy and Performance in Measurement Tools

Calibration services are essential for ensuring the accuracy and performance of measurement tools in various industries such as manufacturing, engineering, healthcare, and more. Calibration involves comparing the measurements of a tool or instrument to a known and traceable standard to determine any deviations and make necessary adjustments to ensure accuracy. This process helps to maintain the reliability and consistency of measurements, which is crucial for quality control, compliance with industry regulations, and for producing accurate results in various processes and applications. Professional calibration services are typically performed by accredited laboratories or technicians who have the expertise and equipment to calibrate a wide range of measurement tools such as scales, pressure gauges, thermometers, flow meters, and more. These services may include on-site calibration, where technicians visit the client's facility to perform the calibration, or off-site calibration, where the tools are sent to a certified lab for calibration. Regular calibration of measurement tools is necessary to ensure that they continue to meet accuracy and performance requirements. It also helps to identify any issues with the tools early on, preventing potential errors or safety hazards. Overall, calibration services play a critical role in maintaining the reliability and precision of measurement tools, which is essential for the smooth operation and quality assurance in various industries.

Essential Factors to Consider When Selecting Calibration Services

When selecting calibration services, it is essential to consider factors such as the accreditation of the calibration laboratory, the expertise and experience of the technicians, the range of capabilities and technical expertise, the turnaround time for calibration services, the quality of the calibration equipment and the traceability of measurements to national or international standards. Additionally, consider the cost of calibration services and the customer service and support provided by the calibration service provider. These factors are crucial in ensuring the accuracy and reliability of calibration services for your specific needs.

تعليقات

إرسال تعليق